Fix it Yourself

I have done all the work on my Jeeps. of course with a lot of help. A service manual and quite a few phone calls.

Oil Change

Changing Your Oil

1. Park on a level surface and set the parking brake after putting transmission in "Park". Before you start this exercise, your Jeep should be cooling down from having been operated up to a temperature. You can start it and allow it to idle up to around 150 degrees or more then shut it off, leave it for 10 minutes, and then start the process. Or you can wait a while after having driven it at full temperature. You might also block your wheels as long as you will be under there. Hey, I'm all about safety.

2. Spread newspaper under your Jeep's oil pan from one wheel to the other and all the way up to the front bumper.

3. Open the fill cap. The Murphy's Law for fluid changes says that after you have drained a fluid from your Jeep, the fill cap will not come off and your vehicle will be totally disabled. ALWAYS TEST THE FILL CAP BEFORE OPENING THE DRAIN. This is why your Jeep cannot be at 210 degrees Farenheit when you change the oil. The fill cap is designed to not open until the engine has cooled significantly. You won't be able to get it off. Don't force it, or it will explode and plastic shards will go into your engine, and you will have to get it towed in. Yes, someone actually did this. One thing I have on my to-do list is to get a replacement fill cap without this silly "feature."

4. Place plastic catch bin under drain plug. The catch pan needs to be big, because oil will splash at first, then come out in a powerful stream, and then drip straight down. And, if there is a breeze, it will blow left and right. Get a nice, huge pan to catch it in.

5. Open Drain Plug with 16mm socket wrench. You will turn it and turn it with your hand before oil suddenly shoots out and gets all over your hand. And, you will drop the plug in the dirty oil. It happens every time. Two warnings here:

OIL MAY BE HOT! Don't drain your oil when the engine is at 210 degrees, or you will fry your hand when the oil comes out. Let the engine cool a little.

WATCH OUT FOR HOT ENGINE PARTS! In particular, I would warn you against the 3rd degree burn I got from the exhaust manifold. It is the silver pipe running under the oil filter from front to back. Touch that thing when it is hot, and your skin will come off and stick to the pipe and fry in front of your eyes. Mine actually caught fire and burned away right in front of me. I will always have a scar. So, be careful what you touch while wrestling under your Jeep.

6. Allow oil to drain for at least 20 minutes. Go inside, drink some water, put oily hand prints on your girlfriend or wife, and strut around like the magnificent peacock you now know yourself to be. Snort and and scratch triumphantly.

7. Replace drain plug. This is important, because if you forget this step, all of the new oil will pour out of the bottom of the engine when you put it in, and your Jeep will be disabled.

Screw in the plug after the oil draining out slows to a slow drip-drip-drip. If it is a thin stream, let it finish. Be patient.

Finger tighten the plug. Then get out a torque wrench and wrench it down to 20 ft-lbs (2003-2005 Jeep Wrangler TJ torque specification - check your factory service manual for the correct torque for yours).

8. Move the oil catch pan. Put it under the oil filter now that your Jeep's drain is plugged. You're going to pull off the filter and put on a new one. Oil will come out when you do this.

Be careful! Watch out for hot things, battery posts, alternator cable connections, and other things that are really hot or have electricity in them.

9. Reach in and unscrew the filter. You should be able to do this by hand. I have never needed an oil wrench. If your hands are greasy, wash them, or put on gloves, and then try to unscrew it. When it pops off, oil comes out and you might startle and drop the filter into the pan. LOL! That's OK. You're done with that filter. Make sure the rubber gasket came off with the filter and isn't still stuck to your Jeep. If you had a crummy filter on their before, it might have come off.

10. Clean up the mess. Get a shop towel or paper towels and get the oil that spilled off of your engine block or it will smoke and burn when you start your engine. Be careful of wiping hot things, like the exhaust manifold, which will be really, really hot.

11. Open the quart bottle of oil and pour into bottle cap. You will put this oil on the new oil filter.

12. Open the oil filter, and lubricate the rubber gasket. Stick your finger into the bottle cap of new oil, and rub oil onto the rubber gasket on the new oil filter. This oil will help the gasket get a good seal on when you screw it to the block.

13. Install new filter. Hand tighten it until it is hard to turn. That's far enough. It doesn't have to be on to tight it will not turn any more. As soon as it resists really hard, you're done.

14. Pour in new oil. Stick the funnel into the oil fill hole, and pour in the oil - not too fast. Pour in six quarts

Change your Air Filter

1. Open the air box by lifting the top up and pulling it back toward the battery. WARNING: Do not touch the red wire coming out of your alternator nor the postive terminal on the battery. Jeeps usually come with these uncovered and touching one could be quite shocking.

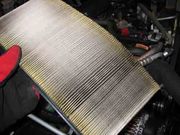

2. Pull out the air filter and look at it. If it is dirty, you need to replace it. But here's the good part - if it isn't very dirty, you can put it back and save your new filter for the next engine check point - maybe 3,000 more miles or so. Only change it if you think it is dirty enough to be changed. If you just see a little bit of dust and white paper, put it back.

3. Put in the new filter, or the old one. If you are putting in a new one, it might not fit right. Surprise! The one that I bought this time around had been formed badly at the factory, and the foam rubber had extra pieces on it that made it not fit into the air box. I used a box cutter to cut off the extra rubberized foam. It is essential that the air filter fit snugly into the air filter box, otherwise, dirt will go around it.

4Put the lid back on the air box.

5 Snap the five clips back into place, starting with the most difficult, the one on the passenger side squeezed up next to the fuse box.

6All done! Do a happy dance and close back up your hood.

Spot Checking Your Jeep During Service

Tire Rotation

Good to do every 6,000 miles.

Lug nuts on a Jeep Wrangler are 1/2x20 with a 60 degree cone, should you need to get more and replace them.

Directions for Rotating Five Tires

1. Set my parking brake. I make sure it is pulled up really good and that the car cannot roll. If I can pull the handle past half-way and the brake doesn't set, then I STOP NOW. I must have my rear drum brakes serviced before I continue. I want a fully operational parking brake before I do something like this.

2. Put the transmission into park. Automatics must be in park.

3. Block all four corners. I place the wheels blocks in front of and behind each tire so that they are touching the tire. This will provide extra safety against the Jeep rolling away from me and coming off of the Jack.

4. Remove spare tire. Pull off the spare and put it near the wheel that you are going to replace with it using the pattern for five tire rotation given below.

5. Jack up one wheel by lifting up the axle tube as recommended in the owner's manual diagram. Place a jackstand under the axle tube. Pull off the wheel. Put on the spare. Put on the lug nuts until the wheel is on. Do not torque the lug nuts down tight yet. Just put them on until they begin to resist and the wheel is flat against the hub. Tighten them in a star pattern.

6. Lower the wheel. Remove the jackstand and slowly lower the jack so that the wheel sets back down on the ground.

7. Torque the lug nuts. Tighten the lug nuts to the correct torque in a star pattern as the graphic shows.

8. Repeat 5, 6, & 7 on the remaining wheels working your way around using the five tire pattern in the graphic.

1.Go to your local Jeep stealership's parts department and purchase one Mopar air filter. I've purchased a Fram and an STP before, and they were obviously made of cheap stuff and did not fit in my air box tightly, meaning that dirty air might have gotten around them and they might not have filtered well. In this case, the OEM air filter is best. It's expensive - almost $30.

2. Put on your mechanic's gloves or some work gloves.

3. Open your hood and prop it up solidy.

4. Snap open each of the five clips holding the air box together. I did this once without gloves and cut myself because the first one was on really tight. Wear work gloves.

1.Go to your local Jeep stealership's parts department and purchase one Mopar air filter. I've purchased a Fram and an STP before, and they were obviously made of cheap stuff and did not fit in my air box tightly, meaning that dirty air might have gotten around them and they might not have filtered well. In this case, the OEM air filter is best. It's expensive - almost $30.

2. Put on your mechanic's gloves or some work gloves.

3. Open your hood and prop it up solidy.

4. Snap open each of the five clips holding the air box together. I did this once without gloves and cut myself because the first one was on really tight. Wear work gloves.

1.Go to your local Jeep stealership's parts department and purchase one Mopar air filter. I've purchased a Fram and an STP before, and they were obviously made of cheap stuff and did not fit in my air box tightly, meaning that dirty air might have gotten around them and they might not have filtered well. In this case, the OEM air filter is best. It's expensive - almost $30.

2. Put on your mechanic's gloves or some work gloves.

3. Open your hood and prop it up solidy.

4. Snap open each of the five clips holding the air box together. I did this once without gloves and cut myself because the first one was on really tight. Wear work gloves.

What are differentials?

Differentials. When you first look under your front bumper, there sure is a bunch of stuff under there. But, when you know what you are looking at, the Jeep front end is really quite simple. Highlighted above in yellow is the differential - AKA "The Pumpkin" - AKA "the diff". The differential is the blob in the middle of the axle where the drive shaft and the axle connect. Inside that thing are lots of big, heavy-duty gears that make the turning of the driveshaft transmit to the turning of each wheel. There are two differentials, one in the front and one in the back.

Track Bar. You can also see highlighted the track bar, which connects the axle to the frame. There is one in front and another in the back. It keeps the axle from floating left and right so that all four wheels line up with each other. Without it, your left side wheel might stick out and your right side wheel would be too far inside, and your wheels would wander around back and forth.

Drag Link. The drag link is another bar like the track bar that connects the right wheel's ball joint with the steering column. When you turn the steering wheel, the column turns, and it pulls the drag link back and forth, which pulls the ball joint. It has a turnbuckle on it and two bolts that hold it tight so that you can adjust it to make your steering wheel straight when your wheels are pointed straight. The shock absorber looking thing on the drag link is the steering stabilizer. It helps prevent vibrations from all of these connecting rods going down the road hitting bumps.

Steering Tie Rod. This bar goes from the drag link end on one side to the driver's side wheel on the other. It is adjustable, just like the drag link, so that you can set the toe-in when doing a front end alignment. Otherwise, it pulls the driver's side wheel when the passenger wheel turns.

You will need to know what these are when you get under your Jeep's front end to do your differential service, because on a stock Jeep that is not lifted, the track bar gets in the way of you reaching certain bolts unless you put the front end up on a jack stand. The tie rod gets in the way when you are trying to take the cover off and put it back on. If you get confused while trying to do your diffs, and you post a message asking for help, you don't want to have to say "What is that thingy next to that other thingy? It is in my way."